Building My Own 50Ah LiFePO4 Lithium Battery Pack

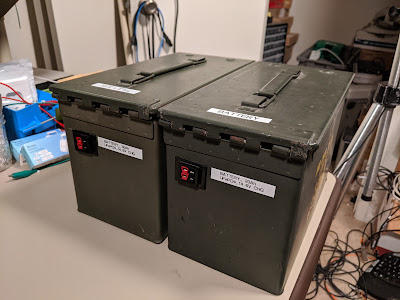

Several years ago, I had purchased a 20Ah 12V Lithium Iron battery pack from Bioenno for my various 12VDC projects. To help protect it, I ultimately built it up into a 50cal ammo can with a dual panel-mount PowerPole connector on the outside, which has proven really nice as far as battery boxes go:

To do this, I used a trick I picked up from my training for the IPC 620 cable assemblies standard, which is when you're trying to butt solder wires together to use a fine gauge wire to lash the wires together first before trying to flow solder in.

- 20Ah is a decent battery capacity for a small load

- The packaged Bioenno pack left some space inside the box to also store the charger it came with, some PowerPole accessories, etc.

- The fact that you're able to close up the box and use the power connectors on the outside once you're using it is real nice.

- Bioenno battery packs are well packaged and fairly idiot proof since the battery management/protection board is built into the pack so it's hard to really harm these.

So I really liked that project; cut out the mounting hole for the panel mount, build a small harness to plug the battery pack into, and use hard foam to give the pack further protection inside the box.

I was recently hanging out with one of my electronics buddies while he was browsing eBay, and he found a bulk lot of eight raw 50 amp-hour LiFePO4 cells from a seller for about $400. A good deal, particularly because the seller said these had been purchased for a project which ended up being canceled, so these were practically new off the shelf cells!

The problem was, my friend was only interested in building a 4S 12V pack (4 series cells x 3.5V ~ kind of equals 12V), so since my unsuspecting ass was sitting there, and he was so persuasive, surprise! I now own four raw prismatic 50Ah lithium battery cells.

To give you a sense of scale, each of these cells is about the size of a paperback book, with two studs on the top for the positive and negative terminals. The eBay lot happened to come with the cell spacers and busbars, so all that was missing to build these into a full battery pack was a battery management system module and an enclosure.

What finally convinced me to buy into half of this lot was that, based on the measurements, it looked like I'd be able to exactly fit this homemade pack into another 50cal ammo can, so that solves the enclosure issue...

Well... almost. The cell spacers were literally millimeters too wide to fit in the can, so I did need to shave off the exterior dovetails to make them fit...

One lesson I did learn was that apparently when I bought these ammo cans years ago, I didn't realize that this one was missing several of the hinge pins for the lid. The two that were left were also loose enough that as I started drilling on the case, they fell out. So those had to get epoxied back in, and I now know to never buy ammo cans without checking to make sure all of this hardware is still there.

So let's talk about the battery management system for a second, because that's the important part to understand when building a lithium battery pack out of raw cells.

The LiFePO4 battery chemistry is awesome compared to the typical deep cycle lead-acid which I'd normally use for the same applications as this. Higher energy and power density, much higher cycle life, and lithium batteries tend to have a very flat discharge curve, so you get a useful ~13V out of a 4S pack right up until the moment it's entirely dead, where lead-acid has a long slow decline starting at 12.6V down to below 11V, so some of your DC equipment might start misbehaving even after you've only discharged half of a lead-acid pack's capacity.

The problem with LiFePO4 compared to lead-acid is that it is also nowhere near as forgiving or abuse tolerant. Granted, LiFePO4 is better than other lithium chemistries, but you still need to be much more worried about issues like over-discharging or over-charging lithium batteries. Abuse a LiFePO4 cell, and it's much more prone to experience permanent damage compared to a lead-acid battery.

The battery management system is an electrical module which has a small wire run to both terminals on every cell, so that it can monitor each cell's individual voltage, and even if just a single cell's voltage falls outside of the acceptable range, the BMS can disconnect the whole pack to prevent further damage. The 45A Daly BMS that I bought also supports balancing, so if any one cell has slightly more or slightly less capacity or resistance than the rest, instead of continuing to drift further and further out of sync with the rest of the pack with regards to their charge state, when this BMS sees a cell reach 3.5V before the others, it starts bleeding 30mA off the cell, to slowly pull it back into line with the rest of the pack.

To help understand why this is so important, remember that in something more traditional like a flooded lead-acid battery, when a cell reaches full charge, it can still pass current to charge other cells by splitting water into H2 and O2. This depletes your electrolyte, but it means the rest of your cells can still come up to full charge. Lithium chemistries don't have any sort of non-catastrophic current leakage like this, so the only way to get current past the highest voltage cell to the others is to use an active device to bleed the current for you.

It also means that LiFePO4 batteries don't have any concept of a higher voltage balancing charge stage like lead-acid batteries have, so as long as you fully charge the pack to the recommended 14.6V and hold it there long enough for the BMS to finish balancing the pack (Which it shouldn't even need to do as long as the cells start well matched) the pack should be fine. Different charge profiles for different battery chemistries and even different manufacturer recommendations inside the same chemistry is a whole rabbit hole in itself, so for this article I'm going to just leave it at "only use a battery charger specifically designed for LiFePO4 to charge these" and gracefully move on.

All of the small wires running to each terminal came with my BMS per-terminated on the small connector block which plugs into the BMS module. Since these are just for monitoring cell voltage and balancing cells, they don't need to carry much current. The two big 10AWG wires molded into the BMS are meant to go between the most negative cell terminal in the pack (blue wire) and the charger/load (black wire), so that the BMS is able to disconnect the pack from everything else if it decides that something is wrong.

These high current lines on the BMS were nice. Definitely 10AWG, "ultraflex" so there was more tiny strands which helps with flexibility, and just enough length on them to be useful for what I wanted. The battery line got terminated with a crimp terminal and connected directly to the pack to try and limit resistance.

Since the PowerPole panel connectors I'm using can each accept 10AWG themselves, I wanted to split this single 10AWG wire from the BMS to two wires for the load/charger connections.To do this, I used a trick I picked up from my training for the IPC 620 cable assemblies standard, which is when you're trying to butt solder wires together to use a fine gauge wire to lash the wires together first before trying to flow solder in.

All of the strength and conductivity comes from the solder, but you're not trying to hold burning hot wire and molten metal together while soldering thanks to the lashing.

Don't mind the blood on the finer gauge wire... That was because I was an idiot while lashing these wires together and forgot that I was working right next to a fully charged bank of raw battery cells with exposed busbars. The 30AWG wire happened to brush the other end of the pack while I was winding it, and even though it was only 12V, the lack of any current limiting meant the wire instantly turned into a hot knife in my hands and left me with a pretty nasty burn.

Anyways... two layers of heat shrink later, we've got an incredibly good electrical connection between the BMS and two more short pieces of 10AWG wire to come out to the panel connector.

I made a point of keeping all of the wires short, but deliberately put stain relief loops in the routing so the pack could have some ability to move around in the enclosure while being handled without stressing anything, since I'm building this battery pack for field use instead of as a static install.

Several pieces of hard foam to insulate, cushion, and immobilize the pack inside the metal can. Doesn't leave much of any room in this can for DC power accessories like in my first power can, but I figure when I'm using a 50Ah pack instead of my 20Ah pack, I'm probably running a more significant load so it would be worth putting some more planning into exactly what cabling I'll need (or just bring both and have all my accessories plus 70Ah of capacity.)

Ultimately, I'm really happy with how this pack turned out, and it was only about $300 for all the raw components to build a pack which still has all of the protection and balancing features that I'd require in a portable field-use battery pack like the off-the-shelf one that I originally bought from Bioenno.